Automatic magnesium oxide mgo sandwich panel production line

Automatic magnesium oxide mgo sandwich panel production line

Couldn't load pickup availability

The price is only for reference , the specific cost will according to your requirements and destination port.

The Automatic Magnesium Oxide Partition Board Making Machine is designed for efficient production of high-quality Mgo boards. This advanced production line automates key processes, ensuring consistent board thickness and density while reducing labor costs. Ideal for industrial-scale manufacturing, it integrates precise material mixing, forming, and curing, resulting in durable, fire-resistant partition boards that meet stringent industry standards. This machine enhances productivity and product uniformity, making it an essential solution for modern construction material manufacturers.

Automatic magnesium oxide mgo sandwich panel production line

| MGO Machine Parameter | |

| Machine Capacity | Now can up to 2000pcs per shift ,we still update our technique |

| Machine advantage | With lots of machine patent |

| Finished board thickness range | 3-20mm |

| Finished board type | Sanding mgo board and normal mgo board |

| degree of automation | Full automatic machine and semi-automatic machine ,can customized |

| Raw material | MGO; Mgcl2 /magnesium sulfate ; perlite; saw dust, etc. |

1:Feeding mgo board material system with full Automatic

|

With this system All the material can be mixed as certain proportion,high effective ,also the most important thing is our engineer can help you adjust the material proportion according to the range of different factor,which is have most relation with the final board quality

|

2:MGO board forming machine

| Multifunction board making machine is the main equipment for the wet extrusion molding for high standard decorate board,it is also the prior choice for the high-grade plate manufacturers in China.After research development and technology accumulation for years,the machine with the advantage of high precision,large capacity,easy operation,good practicality and stable property,etc.It is widely used for Interior wall decorating plate,out wall heated board,sanding veneer,Core board of fire door,fiber cement board,etc for construction and decorated material. magnesium oxide board production equipment |

|

Power(KW) |

6.25 |

7.75 |

|

Max transmission speed(m/min) |

18 |

18 |

|

Layer |

2 |

6 |

|

Capacity(Hour) |

300 |

300 |

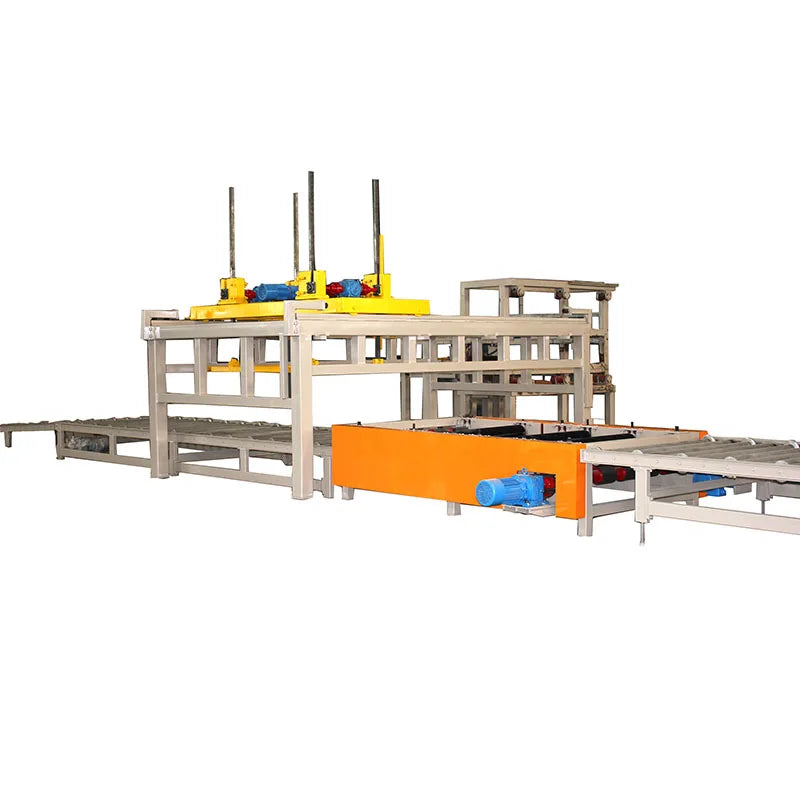

3:Automatic loading/unloading machine

|

Automatic loading/unloading machine is the necessary machine for upper and bottom frame, stacking and curing.It adopts hydraulic upright balance lifting, with the function of automatic tally, automatic ferry, etc., and it replace the manual operate,greatly reduce the labor intensity and improve the operating efficiency and product quality.With the advantage of easy operation,stable property and good security,etc. magnesium oxide board production equipment

|

|

Model |

Power(KW) |

Loading(T) |

Main Roller Speed(m/min) |

|

Shift Type |

8 |

3.5 |

22 |

|

Separate Type |

4 |

3.5 |

22 |

4;Automatic demould and mould clean system

- Frame 4mm steel plate bending,

- PVC seamless belt,

- galvanized belt roller,

- 1.5 kilowatt drive motor,

- overall size: 0.8×3.9×26 meters,

- single machine power: 9KW;

5:Automatic Suction Machine

- capacity: 6 standard boards/minute

- Gear electric synchronous lifting, motor drive,

- displacement servo positioning,

- water circulation vacuum pump,

- square tube frame, linear guide rail,

- surface spray treatment,

- overall size: 2.4×3.2×4.5m,

- single machine power: 9.2KW;

- capacity: 6 standard boards /minute.

6:Automatic cutting machine

- Frame Q235

- motor displacement

- linear square guide rail

- high-speed cutting

- length adjustable

- surface spray treatment

- dimensions: 2.6×1.3×5.7 meters

- single machine power: 2.95KW

- capacity: 8 standard boards/min

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: What certificate do you have?

A: We have ISO and CE certificate.

3. Q: How does your factory do regarding quality control?

A: We have a special QC department in charge of products' quality.

4. Q: How long is the warranty period?

A: All of our products have one year warranty.

5. Q: What's the main market of your company?

A: We have customers all over the world.

6. Q: How much production capacity of your company one year?

A: This depends on your needs.

7. Q: Where is your factory located? How can we visit there?

A: Our factory is located Qingdao before you arrive Qingdao Liuting airport ,we will arrive the airport in advance to pick you